Core Product Advantages

Extreme Lumen Output

Provides light levels comparable to traditional grid lighting (HPS/Metal Halide), but with far lower power consumption.

Industrial Grade Autonomy

Guaranteed operation for up to 10 rainy days, ensuring reliability for critical infrastructure projects worldwide.

Advanced Thermal Engineering

Proprietary housing design dissipates heat efficiently, protecting the powerful LED chips and battery from premature failure.

MPPT & Dynamic Dimming

Intelligent controllers maximize charging efficiency and allow complex programming to conserve energy and match project requirements.

Maximum Output: Defining the Standard for High Lumen Solar Lighting

The High Lumen Solar Lights category is defined by a singular, non-negotiable requirement: delivering the maximum possible brightness (measured in Lumens) while maintaining reliable off-grid autonomy. These products directly compete with high-pressure sodium (HPS) and metal halide fixtures, but offer superior energy efficiency and zero operating costs. This category encompasses our most powerful street light, flood light, and high-mast area lighting solutions, specifically engineered for industrial, municipal, and commercial applications where light output and consistent performance are paramount.

Achieving truly high lumen output requires a complete system redesign that pushes the limits of solar technology. Key features include oversized solar panels (often utilizing the split-system configuration to accommodate the surface area needed), large-format, high-voltage LiFePO4 battery banks (e.g., 12.8V or 25.6V systems for higher efficiency), and densely packed, high-efficacy LED chips (e.g., using Cree or Bridgelux chips) paired with advanced thermal management.

The engineering challenge in this segment is heat management. To produce 15,000 to 30,000 lumens, the LED array generates significant heat. Our solution involves proprietary die-cast aluminum alloy housings with massive, integrated heat sinks and internal air convection channels. This robust thermal dissipation is crucial not only for the lifespan of the LED chips (maintaining the 50,000+ hour rating) but also for the long-term stability of the LiFePO4 battery, ensuring it operates within its optimal temperature range, even in tropical or desert environments.

Furthermore, the high power draw of these lights mandates the use of highly intelligent controllers. Our systems utilize advanced MPPT (Maximum Power Point Tracking) and sophisticated software programming. This software allows for precise, multi-stage dimming profiles (e.g., 100% output for 2 hours, then 50% for 3 hours, then motion-activated for the rest of the night). This dynamic load management ensures that the huge battery capacity is conserved and allocated effectively, guaranteeing the critical 5-10 day rainy-day autonomy required for high-risk, critical infrastructure projects.

By investing in our High Lumen Solar Lights, project developers and municipalities secure a long-term, powerful lighting solution that reduces installation complexity and eliminates energy costs. We provide detailed photometric reports (light plots) for every model, ensuring compliance with local government safety and lux-level standards for highways, large parking lots, ports, and industrial campuses, validating the superior performance of our products against traditional grid-tied alternatives.

Technical Specifications (150W Industrial Model)

| Product Series | NL-HL-150W |

| Light Source | High-Efficacy Cree/Bridgelux Chips |

| Nominal Power | 150W |

| Lumen Output (Max) | 16,000 - 18,000 LM |

| System Voltage | 12.8V / 25.6V (High Voltage) |

| Solar Panel | External Monocrystalline Silicon, 200W - 250W |

| Battery Type | High-Density LiFePO4 Bank, 12.8V/100Ah |

| Charging Efficiency | MPPT Controller, >99% Tracking Efficiency |

| Autonomy (Backup Days) | 7 - 10 Cloudy Days |

| IP Rating | IP66/IP67 (Fixture and Battery Box) |

| Installation Height | 10 - 14 Meters (High Mast) |

| Thermal Management | Integrated Massive Die-Cast Aluminum Heat Sink |

get in touch with us

Heavy-Duty Installation and Calibration

Structural Check

Verify the high-mast pole foundation and structure can handle the weight and wind load of the large solar panel and fixture assembly.

Panel & Battery Mount

Install the heavy-duty solar array and the high-voltage battery bank (often at the base of the pole or on the cross-arm).

Fixture Hoisting

Secure the high-wattage fixture onto the pole arm, using appropriate lifting gear due to the component weight.

Controller Programming

Utilize the programming interface (via PC or remote) to input the precise dimming schedule and operation logic as required by the project specifications.

Comprehensive Application Scenarios

High-Speed Highways & Tunnels

Meeting strict lux-level requirements for high-mast lighting over wide, multi-lane highways and toll plazas.

Ports and Container Terminals

Providing powerful, reliable illumination for large storage and operational areas that run 24/7.

Industrial and Mining Complexes

Durable, high-output lighting for harsh, remote environments with heavy equipment and demanding schedules.

Large Public Parking Structures

Ensuring maximum security and clear visibility across large commercial and municipal parking lots.

Commercial Project Snapshot

| Minimum Order Quantity (MOQ) | 20 Units (High-value project focus) |

| Lead Time (Typical) | 35-45 Working Days (Complex component sourcing) |

| Packaging | Custom Plywood Crates/Heavy-Duty Skids |

| Certifications | CE, RoHS, IP67, IES/Photometric Reports |

| Raw Materials Focus | Cree/Bridgelux Chips, MPPT Controller, High-Gauge Aluminum |

| Customization Options | High-Voltage Battery Bank Sizing, IES Light Distribution, IoT Integration |

-

1

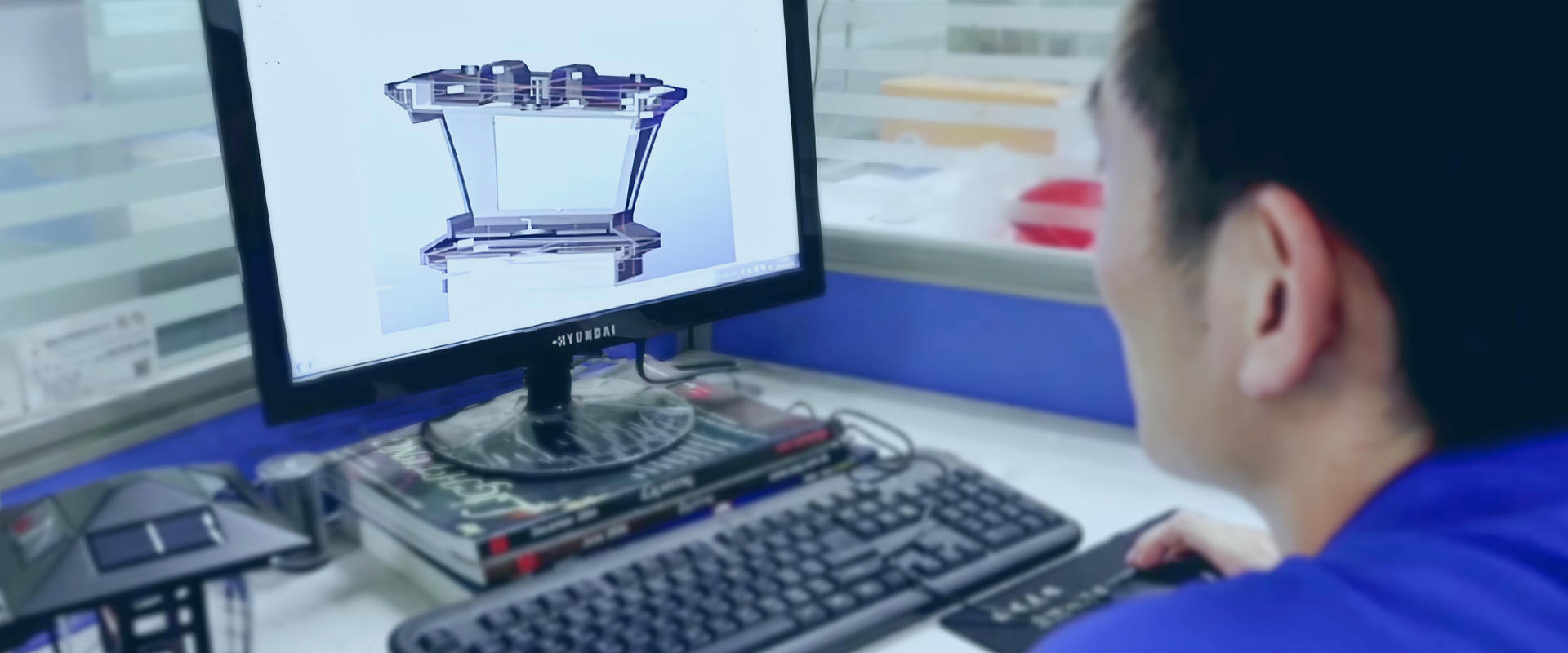

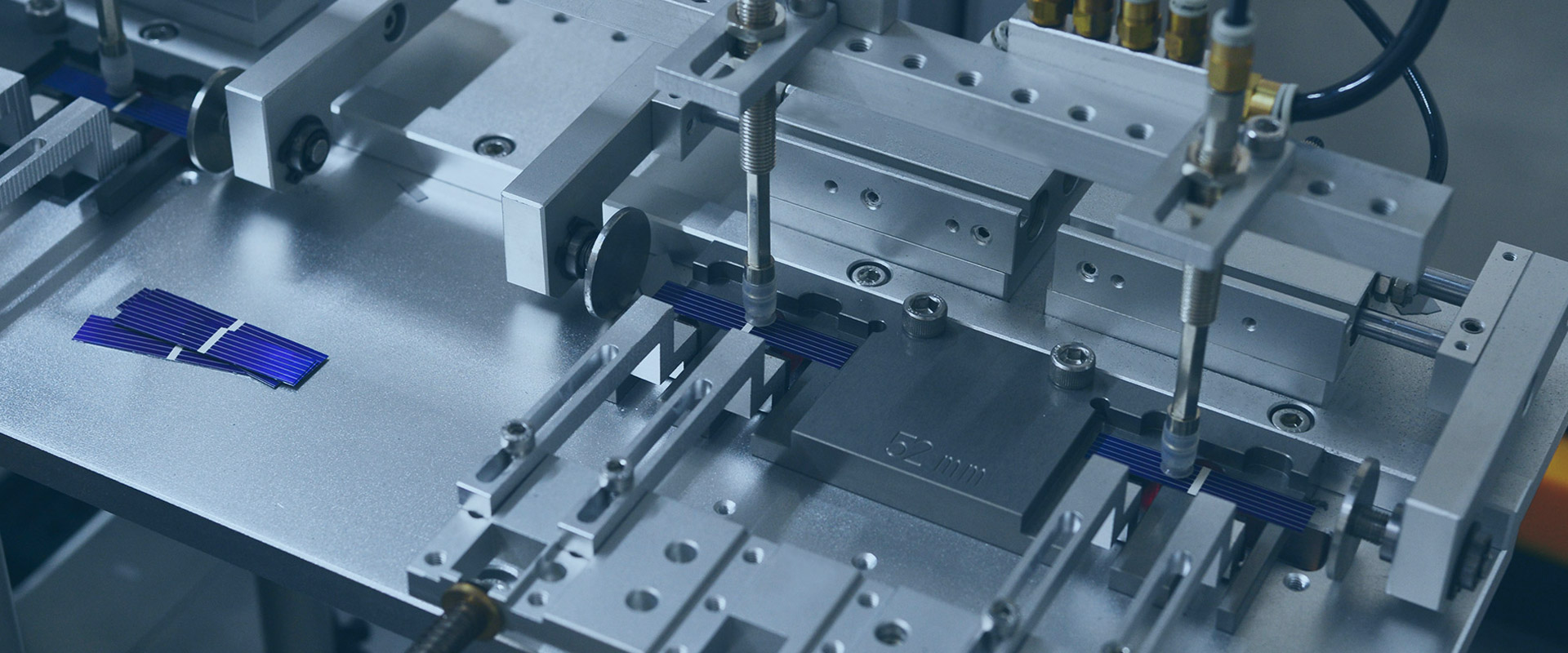

1Customization

-

2

2Quality

-

3

3Advanced

Equipment

Frequently Asked Questions (FAQ)

Q: What is the highest wattage you offer in this high lumen category?

A: We offer standard models up to 200W, and custom industrial solutions can reach up to 300W with appropriate battery bank sizing.

Q: Why is a high-voltage battery system (e.g., 25.6V) better for high lumen output?

A: Higher voltage reduces the current required to deliver the same power (P=VI), minimizing heat loss in the wiring and improving overall system efficiency.

Q: How accurate is the MPPT controller in maximizing charge?

A: Our MPPT controllers typically achieve 99.5% tracking accuracy, significantly outperforming standard PWM controllers, especially on cloudy or partially shaded days.

Q: Can these lights integrate into a city-wide smart lighting system (IoT)?

A: Yes. We offer optional integration modules (e.g., LoRaWAN or Zigbee) that allow remote monitoring, fault reporting, and centralized control of the entire lighting network.

Q: What type of optical lens is used to distribute the light so widely?

A: We use high-grade PC or PMMA lens with Type II, Type III, or Type IV road light distributions (IES files) to ensure optimal light uniformity for specific road widths.

Q: Is the battery bank secure from theft or vandalism?

A: The external battery box is typically designed with anti-theft bolts, heavy-duty housing, and can be mounted high on the pole or secured within a concrete base.

Q: What is the typical maintenance frequency for these powerful systems?

A: Recommended maintenance is minimal: physical inspection every 12 months and cleaning the solar panel surface every 6-12 months, depending on the environment.

Q: What is the minimum lux level guaranteed under the warranty?

A: The warranty guarantees that the system will meet the designed lux level requirement for the first year and maintain a specified percentage of that level throughout the warranty period.

Q: Can the color temperature (CCT) be customized?

A: Yes, we offer CCT ranging from 3000K (Warm) to 6500K (Cool), though 5000K is standard for high-visibility industrial applications.

EN

EN

English

English Français

Français Español

Español

.png?imageView2/2/w/325/h/325/format/jpg/q/75)